Discoveries are always a wonder to behold. For generations, humanity strived to excel in this field to bring about significant changes to the world. Through countless experimentations, failures, and successes, the fruits of hard labor manifested themselves in the forms of technologies that revolutionized all sectors of human living.

These are the revolutions shaping the construction industry today:

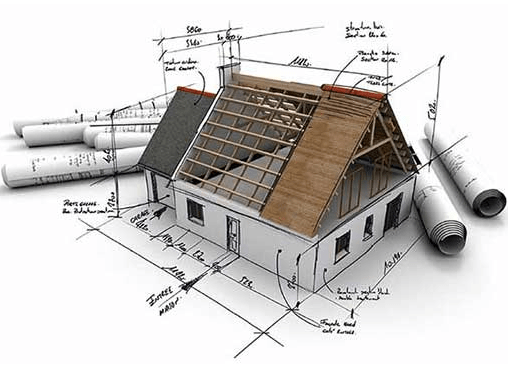

#1. Computer-Aided Design (CAD)

Architects, drafters, skilled stonemasons, and builders produced some of the world’s most stunning buildings during the Middle Ages, employing groundbreaking design and construction technologies. Due to the slow changes in the construction industry, these approaches remained essentially unaltered for millennia.

However, during the middle of the twentieth century, computer-aided design (CAD) appeared, permanently altering construction for the first time in many years. Disagreements during the design process were made evident. Separate systems, electrical conduits, and high-voltage alternating current ducting, for example, were once a source of consternation for architects and builders working with two-dimensional plans and section drawings.

It works side by side with other technologies to improve efficiency and provide more creative means for visualization. One of the best examples of such a union is 3D printing. Now, the future of 3D printing in construction is exciting and genuinely revolutionary for many who do many model buildings.

#2. Prefabrication

It can be challenging to piece together massive, sophisticated components on-site when exposed to the weather. The growth of off-site fabrication is significantly improving this process’ efficiency. For example, a large heat exchanger manufactured in a vendor’s shop will reach the site ready to use. Prefabrication results in better inventory management of parts and materials and increases efficiency and productivity.

While waste and inefficiency decrease, return on investment rises. When components like pump units, heat exchangers, compressors, and instrument panels are fabricated in-shop rather than on-site, they save a significant amount of time on the schedule.

#3. Building Information Management (BIM)

Building Information Management (BIM) has proven incredibly versatile, allowing architects, engineers, contractors, and subcontractors to collaborate on the minute aspects of design and construction using the same computer model and database.

As mechanical, electrical, and plumbing (MEP) professionals are aware, BIM entails all project stakeholders working together on a complete 3D model that includes all of a building’s functional systems, such as HVAC and electrical installations, and walls’ aesthetics, windows, and roofs. You can also incorporate some aesthetic access doors into the plan for added safety and convenience features.

Since BIM is a collaborative process from start to finish, it enables all project stakeholders to analyze and interpret design decisions and identify interferences and other problems before construction begins on site. Working as a unit saves MEP contractors a lot of time and money because construction doesn’t start until all parties have submitted their ideas, ensuring that the identification and resolution of disputes are quick, easy, and happen before the groundbreaking on-site.

#4. Modular Construction

Thanks to the growth of modular construction, not only components like those stated above can now have their manufacturing process off-site, but entire buildings as well. The manufacturing of these modules uses the same materials and specifications as on-site buildings, yet they cause significantly less environmental impact.

Components are delivered to the job site as needed. Today, because you can do roughly 70% of construction in the form of parts, it has entered the ‘just-in-time’ manufacture and delivery domain, which decreases on-site scheduling and waste.

#5. Self-Healing Concrete

Concrete’s utilization is far-reaching in buildings, yet it comes with many issues. It is prone to cracking, which is mainly because of exposure to chemicals and water. It is terrible news because cracks expand, and as they grow, they enable more water to enter the concrete, corroding the reinforced steel within. However, there is a solution on the way.

Self-healing concrete with bacteria and microcapsules in the mix – it’s a potential revolution at this point, but it’s coming. When water infiltrates, these clever supplementary elements germinate and generate limestone, filling the gap and preventing corrosion in steel reinforcements.

#6. Personal Protective Equipment (PPE)

Although personal protection equipment (PPE) is not as technically sophisticated as the other technologies out there, there is no doubt that it is helping to revolutionize the construction industry in terms of health and safety throughout the years. According to a 2008 performance evaluation of the last act. The number of fatal injuries to employees in the UK declined by 73% between 1974 and 2007, while recorded nonfatal injuries fell by 70%. The figure of fatalities in the construction industry fell to a record low in 2005-2006.

Final Thoughts

There is so much more that is going in the construction industry as we speak. It will be exciting to see what else is there for the next generation of developers as technology continues to drive things further into new heights. Consult a licensed professional for more information and other options that you need for your next project.